Quality Management

- Home

- Quality Management

World-Class Quality Management for Assurance

LTR has an independent QC laboratory with our testing equipment that conducts various tests on our plastic rattan and wood boards.

We also have strict inspection processes throughout production, such as raw material screening and production tests.

Through our QC testing based on AQL standard, we ensure our sustainable materials provide any outdoor furniture with superior durability and service life.

Thorough Plastic Rattan & Wood Quality Tests

Elongation Test

The plastic material’s tensile strength and durability are tested by stretching it to 200% of its diameter.

Weathering Test

A weathering chamber allows us to see the physical reaction of our plastic rattan and wooden boards to the elements.

UV Aging Resistance Test

Utilizing 2,000 hours of artificial lighting exposure to accelerate the effects of sunlight exposure, allowing us to determine our material’s durability.

Melting Point Test

We test the strength and appearance of our plastic rattan and wooden boards based on their melting point range.

Metal Testing

All materials go through our metal testing equipment to ensure the materials are free of any harmful materials and comply with RoHS standards.

Temperature & Humidity Test

The test measures our plastic rattan and wood boards resistant to the moisture and heat elements.

Conventional Test

LTR plastic rattans and wood boards’ resistance against physical damages are measured through conventional tests.

Tensile test

This test ensures our plastic rattans and wood boards have a tensile strength of up to 70 Nm.

How LTR Complies with Industry Standards

100% Process Covered

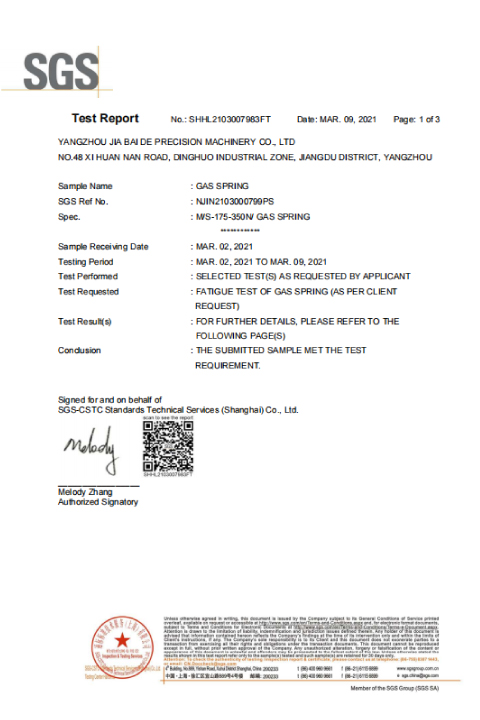

During the production of our plastic rattan and wood boards, several inspection points are set up including IQC, IPQC, FQC, and OQC to cover 100% of the production process. The top-level quality control system we have established ensures that LTR complies with SGS and EU's REACH standards in the quality control process.

98% Good Quality Rate

Using plastic rattan and wood with such high quality rate in outdoor furniture offers numerous benefits, including durability, color retention, low maintenance, and environmental friendliness.

More Reassuring Quality Promise

24 Hour Report

Our QC team provide a detailed quality report within 24 hours upon your request to give you peace of mind on quality issues.

5% Per Thousand Oxidation

About 2% to 5% of high-grade oxidizing agents are utilized to preserve the colour and durability of your plastic rattan and plastic wood board.

100% Bio-friendly

All raw materials are GRS-approved for sustainable resources. We also complies with international standards for waste treatment.