Introduction

Decorative coatings are a very advantageous option for making surfaces more attractive and durable, both indoors and outdoors. This type of cladding enhances the appearance of walls, making them more appealing and adaptable to different decoration styles.

In addition to improving the aesthetics of a room, they can also offer additional benefits such as improved acoustics, fire resistance, waterproofing and surface durability. In short, cladding is a finishing solution used to enhance the appearance of a surface and give it a more attractive and personalised look. They are also an interesting option for those who want to renovate or personalize their home or workplace and can be used in a wide variety of decorative styles.

Recently the technique of using synthetic rattan for the cladding of homes, hotels, resorts and public buildings has become a major trend globally. Synthetic rattan which is a highly versatile and durable material offers perfect finishes for both indoor and outdoor projects. In this article we will talk about the characteristics of rattan sheeting, the usefulness of this type of wall coverings, patterns or ways of weaving rattan sheeting, practical examples as well as the details when ordering this product for your project.

Characteristics and usefulness of rattan sheets.

2.1 Characteristics of plastic wicker woven mat.

Although the technique of cladding walls with different materials is not entirely new, the use of synthetic rattan to carry out this type of project has changed the panorama of interior and exterior decoration. The mechanical and chemical factors of synthetic rattan make this material adaptable to the visions and/or needs of many architects, designers, builders, etc. Synthetic rattan sheet has the following characteristics:

- Resistance, the rattan sheet is a product that is resistant both indoors and outdoors, the material is resistant to different climatic agents, humidity, dust or insects and can be exposed to sunlight and still maintain its colour.

- Flexibility, the rattan sheet can be used for wall cladding and ceilings. During the installation process, the material can be cut into different pieces to suit your needs.

- Versatility, synthetic rattan is a material that can be manufactured in a wide variety of colours, either mixed or mixed, so the rattan sheet can be manufactured in the same way whether it is flat rattan, round rattan, half moon or seaweed.

- Easy installation process, during the installation of a synthetic rattan sheet, very common and easy to purchase and use materials are usually used.

2.2 Utility of the rattan sheet

Rattan sheets are a product that can be used for both interior and exterior wall cladding projects. Rattan sheets can also be used to decorate the ceilings of bedrooms, living rooms or offices. In special projects, this material is also used to cover and decorate structures of a certain building.

Manufacture of artificial rattan sheet and the most requested patterns.

The first phase of the rattan netting manufacturing process is the production of raw material, i.e. the synthetic rattan fibre which is intended to cover and decorate a certain structure. The most commonly used synthetic rattan model in this type of project is the flat rattan, but it is also possible to use the half-moon, round or seaweed models.

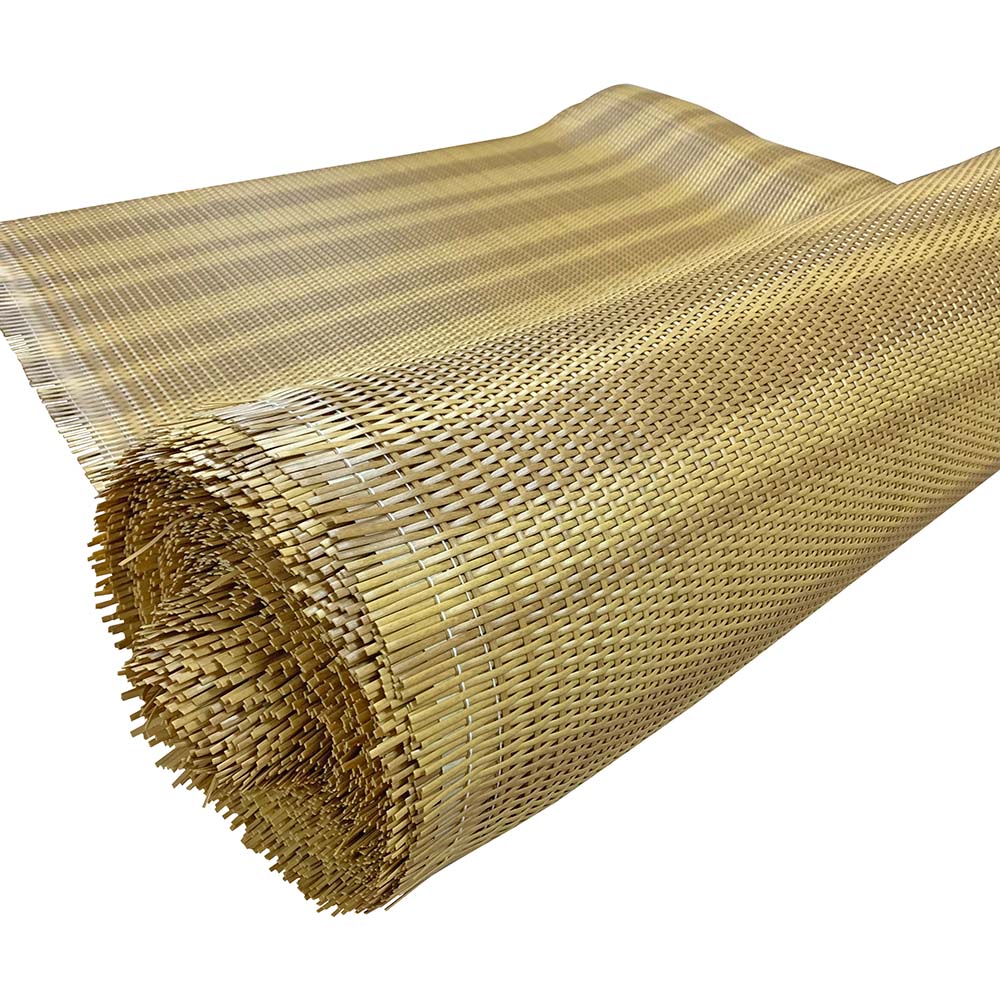

The next step is to determine the measurements of each piece or roll. Although the factory has standardised measurements, we always offer the customer the option of selecting the measurements on which we must manufacture the rattan sheet, that is, the length and width of each roll.

Rattan woven sheet with and without structure

- Rattan sheet without structure

This is the main way of production of this material by many manufacturers. Manufacturers use synthetic rattan fibre to weave the pattern determined by the customer. After the production of the material, the material is delivered to the customer in rolls in his country and during the installation process of the material he will have to make his own structure to adjust the rolls or the rattan mesh to the surface he wants to decorate.

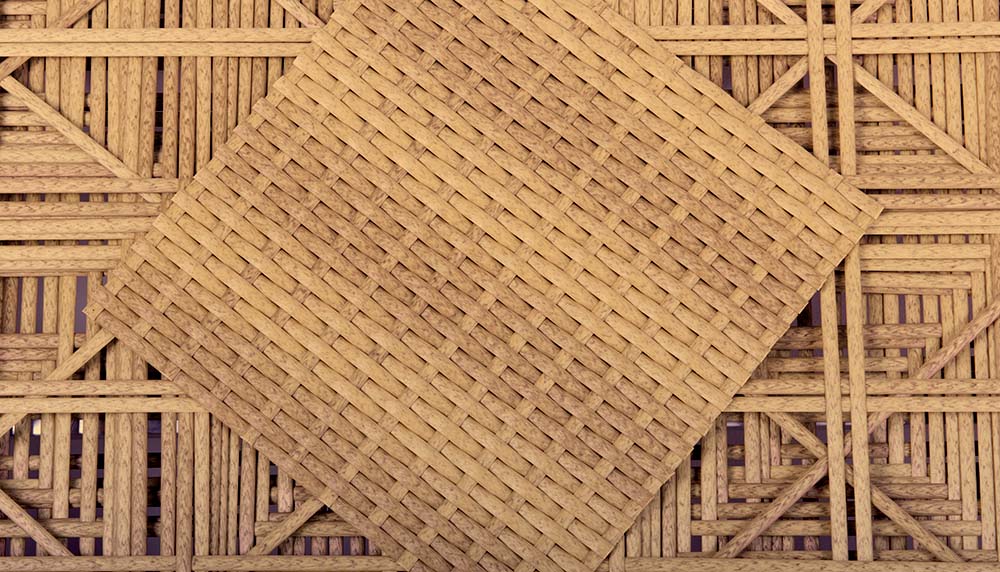

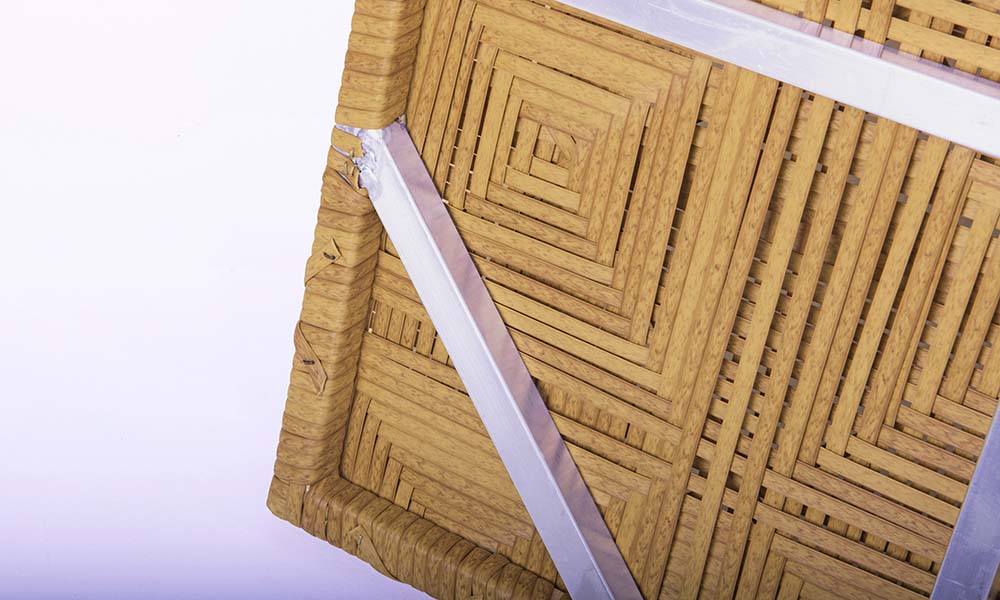

- Rattan panel with structure

This is the second form in which manufacturers offer this product. The manufacturer’s task is to weave the rattan fibre previously selected by the customer over a structure made of either metal, steel or wood. The main factors that drive this technique of weaving rattan sheets are: the lack of experience of customers to install the material when it is in the form of rolls and secondly because there are some patterns or ways of weaving the rattan that are very complex and prevent the material from unravelling or arriving in poor condition at the customer’s location, what we recommend to the customer is to receive the material already previously woven in our factory and we send it in the form of panels or structures covered with rattan.

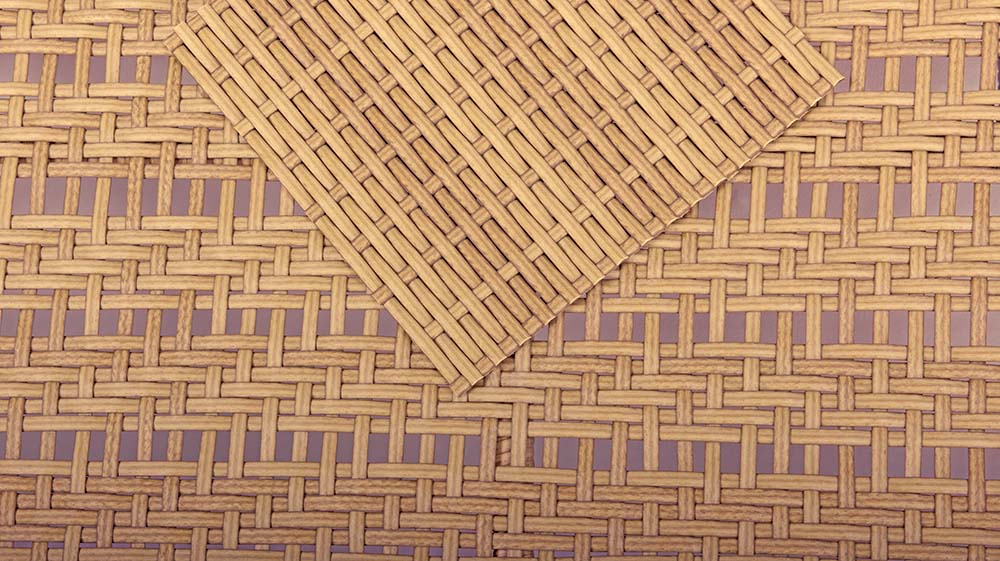

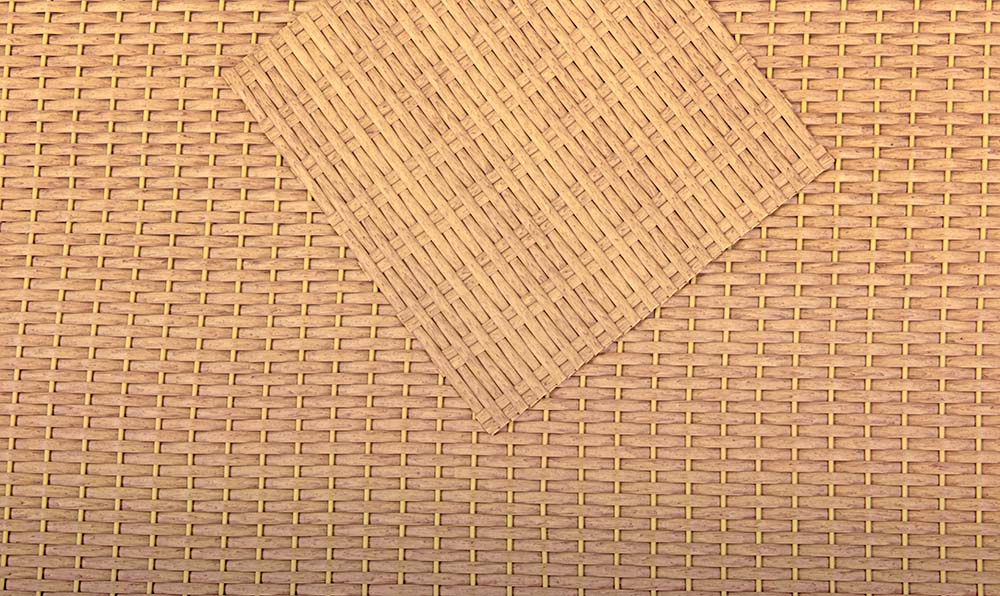

3.2 The Most Requested Rattan Woven Mat Patterns.

When we say patterns, we refer to the way or technique in which the synthetic rattan is used to give a certain shape to the rattan sheet. Nowadays there is a great variety of patterns in which the synthetic rattan sheet can be woven, from simple patterns to complex patterns. You can also weave the synthetic rattan sheet in single or mixed colors.

Installation of the synthetic rattan panel

The installation process of this material is really easy. Whether the customer has received the material in roll form or in panel form, it does not require a lot of materials to complete this task.

If you as a customer receive the material in roll form, depending on the surface you plan to install the material on, you will have to build a structure either out of wood or metal. On that structure is where you will place the material and you will have to make use of a nail gun to fit the material to the structure. In the case of the panels, the process is simpler as the structure is manufactured at the factory and the customer only has to use screws to fit the material to the surface or space they wish to decorate.

Practical examples of the new trend of wall cladding with rattan sheets.

- Panama Project

In this project, the client explained to us his intention of creating a rattan sheet covering the rooms of a luxury resort.

For this project, the client selected the flat synthetic rattan model BM-32449 which had to be woven using a pattern of horizontal and vertical lines. Since the material was delivered to the customer in rolls, during the installation process the customer manufactured wooden structures to fit the rattan sheets on the surface he wanted to decorate.

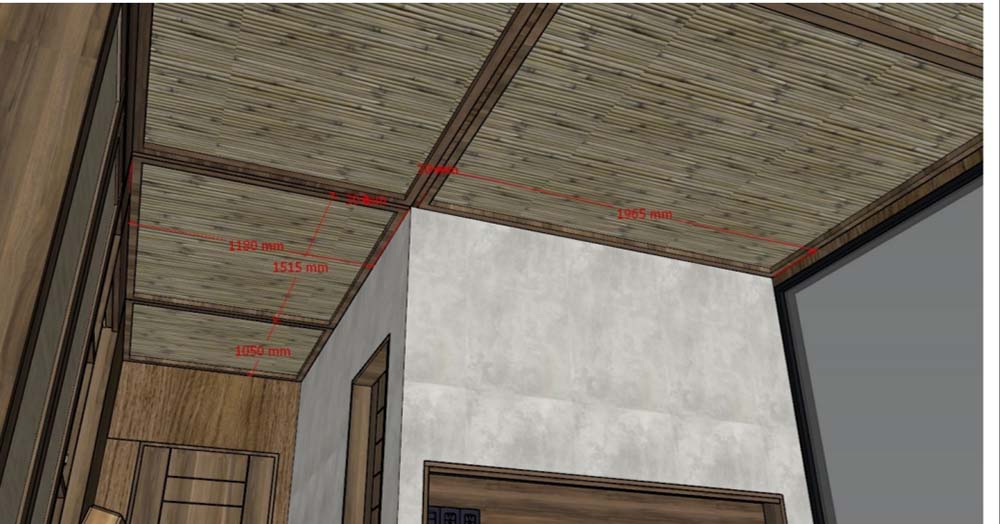

- Philippines Project

This is a project in the Philippines. The essence of the project is not limited to simple decoration. However, our client wanted to create an environment that conveys a sense of nature and open air in his house by covering the roof of his house with synthetic rattan slats. Since the size of the project was 64 square meters, we had to fabricate synthetic rattan sheets in different sizes which were then shipped to the Philippines for installation on the roof of the client’s house.

Steps to purchase the rattan woven sheet.

In previous articles, we have discussed how easy it is to import synthetic rattan, an easy material to pack and transport and there is no need to submit special documents to customs during the customs clearance process. Similarly, it is easy to import rattan sheets. However, there are several details to consider when placing an order for your project.

If you want to purchase synthetic rattan sheets for your decking project, whether for your home, hotel or resort, you must first determine which synthetic rattan model best suits your project, i.e. flat, round, half moon or seagrass synthetic rattan.

After determining the synthetic rattan model, the next step is to determine the pattern in which the rattan netting should be woven. Nowadays manufacturers offer different patterns either in single or mixed colours.

The next step is to determine the measurements of each piece or roll, i.e. length and width. After determining the measurements and based on the pattern you have selected it will be decided whether the material will be delivered in rolls or if the best way to deliver the material is to weave it into the structures first.

After determining all these details, the manufacturing period of the material varies between 12 to 25 days depending on the volume of the order. After finishing the material, depending on the customer’s indications, and the country of destination, the material can be packaged in two ways: in the form of rolls or in a wooden box in which the rolls or the structures are placed. The main reason why the material is shipped in a wooden crate is to protect the material and to prevent it from being damaged during transport from the factory to the customer’s country.

FAQ

- How long does this plastic wicker woven sheet last?

The durability of the product depends on the durability of the synthetic rattan fiber, up to now we can offer 2, 3 and 5-year warranties.

- What is the maximum length and width that your company can offer?

Generally we suggest customers to select a maximum length of 20 meters, while the maximum width can be more than 3 meters.

- Can your company send me samples to confirm the colour I need?

Of course, we offer free samples of any model listed in our catalogue.

- Do all models come in roll form or does it depend on the customer’s choice?

No, the way we manufacture and ship the material depends on the type of project the customer is doing and the model or pattern he selects.

- Can your company offer this material but with the flame retardant factor?

Of course, our company has the technology to make the synthetic rattan flame resistant.

- What is the manufacturing duration of this product?

The manufacturing time of this product varies depending on the volume and specifications of each order, however it varies between 12 to 20 days.

- What colours are available?

This product is available in over 100 colours, we can offer this material in both single and mixed colours.

Conclusion

Nowadays, there are many possibilities for wall coverings both indoors and outdoors. Wall coverings made from natural or synthetic materials with excellent technical properties. From the cheapest to the most expensive, with a wide variety of designs, colours, textures and finishes for any space and decorative style.

Within this wide variety of choices for decorative wall cladding projects we find the synthetic rattan sheet, a material that meets the standards of aesthetics, versatility and durability, easy to install, requires little maintenance, is resistant to different climatic agents so it can be used in both indoor and outdoor projects. Undoubtedly, synthetic rattan sheeting is a highly sought after product among designers, interior designers, hotel, resort and homeowners and a great choice for you if you want your project to stand out and be unique.