Introduction composite lumber for outdoor furniture

A joint study by numerous US universities estimated that around 80% of the plastic produced is discarded. Of this, only 9% is recycled, 12% is incinerated and 69% is landfilled or abandoned in the environment. On the other hand, there is another situation in which a forest area the size of Greece, estimated at 10 million hectares, disappears annually, sacrificed in the name of progress. This destructive dance of figures reflects an inescapable truth: we are polluting and depleting our planet’s natural resources at an alarming rate.

Faced with this situation, many people have sought ways to reduce environmental pollution and deforestation and in this scenario appears Plastic Wood, a product obtained from a technology that allows a new opportunity for plastic waste, using plastic waste as raw material, offering a sustainable solution to large generators and an ecological destination for plastic materials that otherwise would end up in landfill. To be composed of industrial plastic waste, our plastic wood is very homogeneous, achieving a very similar appearance to natural wood. Our company is 100% committed to caring for the environment and promoting the manufacture of products that reduce pollution and improve people’s lives and has been manufacturing plastic wood for over a decade. In this article, we will talk about our production capacity, the variety of models, the quality guarantee as well as the different projects in which you can use this material.

Capacity and production variation

Leisure touch rattan is a company that for more than a decade has focused on perfecting the technique of manufacturing plastic wood planks. Today the company has more than 60 construction machines capable of producing more than 2800 tons of plastic wood per year. Our research and development team has not only managed to improve the technique and make our plastic wood look like natural wood, but we also offer the highest quality to our distinguished clientele, so that they can enjoy a material that has the advantage of resistance to degrading agents, ease of moulding and requires no maintenance. In addition, it is a viable material to use because of its durability, environmental impact and low cost.

We offer different plastic wood finishes, mainly divided into Brushed, flat and embossed.

- Embossed: the model has a concave and convex wood texture. During the manufacturing process, they are pressed with the press wheel mould.

- Brushed: This model has the fine texture of natural wood.

- Planed: During the manufacturing process the surface layer of the wood is planed by the planer to make it flat enough to reveal the grain of the wood in the recipe.

At the same time, each of these plastic wood plank finishes is available in single and mixed colours. The company has not only increased the ability to make plastic wood into the same physical form as natural wood but also can manufacture this material in over 300 different sizes.

Production Duration and Quality Certificates

The time needed for the factory to produce the material tends to vary depending on the volume and indications of each order, as the dimensions of the planks we produce are not standardised. What we do is adapt to the needs of each customer, however, although the manufacturing time is variable, the range of material production is between 12 and 25 days.

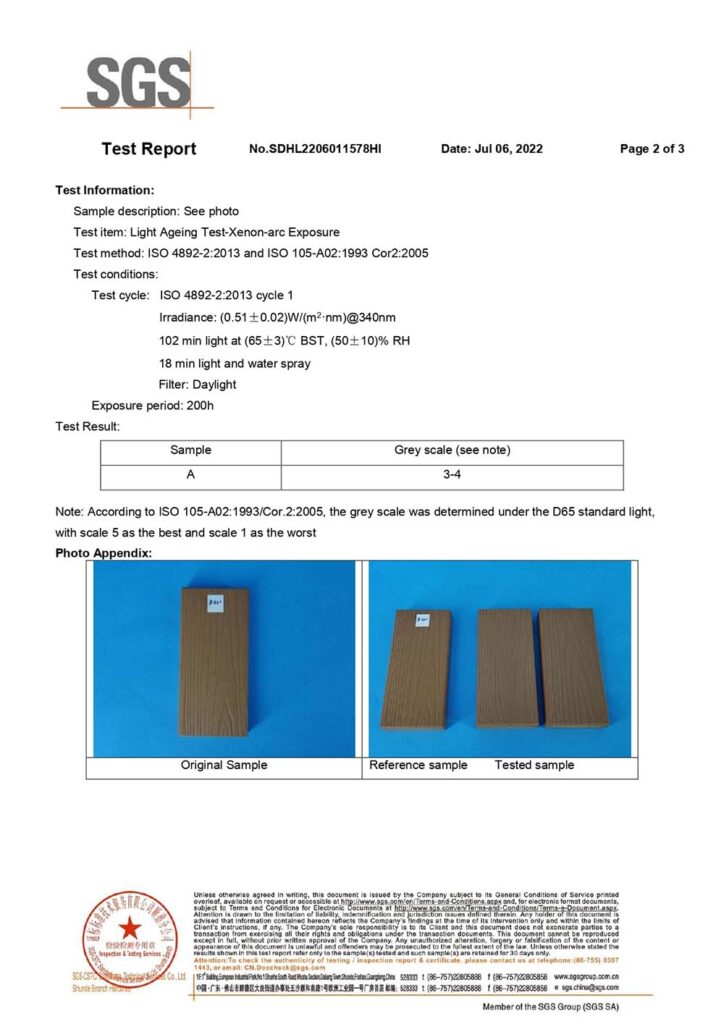

To guarantee the customer’s peace of mind and to offer high-quality material, the company has quality tests that comply with all the quality standards required by international institutions.

The most notable applications of recycled plastic wood Lumber

The main application for which HPDE plastic wood is known is the manufacture of outdoor furniture. The mechanical and chemical factors of this material make plastic wood highly resistant and suitable for this type of environment, however, there are a wide variety of applications in which this material can also be used, among them: the construction of gates, signage, garden accessories, playgrounds etc.

Many construction projects have already been transformed by wood-plastic, but its full potential has not yet been realised. There is a possibility that wood-plastic will begin to appear in more sophisticated structures as construction companies continue to push the boundaries of these materials. The durable and reliable answer to responsible construction in the future is recycled wood-plastic. The timber business may have found its answer in plastic lumber, and in the process, society as a whole became more environmentally conscious. By using this material, the construction industry will have less overall negative influence on the environment, more cheap housing options will be available and more trees will be saved.

FAQ

- Is plastic wood a substitute and a more environmentally friendly alternative to natural wood?

Of course, plastic wood not only imitates the physical appearance of natural wood but also contributes to the fight against environmental pollution as the manufacturers of this material use tons of plastic waste to manufacture a new product, in turn reducing the deforestation of forests.

- Where is your factory located? How long does it take to manufacture an order?

The time it takes the company to produce an order tends to vary depending on the volume and indications of the order, however, under normal conditions, it varies from 12 to 25 days.

- What is the maximum length you can offer per board?

Generally, there is no limit, the choice of the length of each board depends on the needs of each customer.

- Before I order, can you send me samples to check the quality and colour?

Of course, in our factory, we have thousands of samples available for any of our customers.

Conclusion

Our customers care about the forests and we care about our customers. As a new environmentally friendly material, plastic wood (made of PS, polystyrene) has the best of both worlds: performance in all weather conditions and the closest result to wood slats in shape, colour, finish, texture and grain. Plastic wood has the advantages of being UV resistant, all-weather, waterproof, moisture-proof, insect proof, strong plasticity, high environmental protection, no pollution, recyclable, simple installation, no need for daily maintenance and longer life span than wood.

We want to make the best plastic wood, to appreciate environmentalists, making them enjoy fresh, natural, outdoor plastic wood while protecting the environment to the maximum.

侧面图.jpg)

侧面图.jpg)

侧面图.jpg)