Background of Synthetic Wicker Rattan Panels

Are you trying to find more useful information about artificial wicker woven panels? This article might be able to help you understand this material better! As people increasingly seek to connect with nature, there is a growing trend to incorporate natural elements into both indoor and outdoor spaces. Synthetic wicker woven panels, a relatively new form of rattan material, have become highly popular in architectural design. Perfectly blends tradition with modernity, artificial wicker woven panel is commonly used for construction applications such as wall coverings, ceilings, roofing and so on.

Whether in commercial or residential settings, rattan elements can effortlessly bring a sense of relaxation to the area. It is especially favoured in tropical regions, such as the Middle East, and Southeast Asia, and popular tourist destinations such as North America and Europe. In the following paragraphs, Leisure Touch Rattan will explain this material to you, helping you get suitable materials for your diverse projects!

Brief Introduction to Artificial Wicker Woven Panel

Just like plastic rattan strips, artificial rattan sheet is made from eco-friendly PE plastic, which is durable, recyclable and non-toxic. Imitating the natural look and grains of real rattan, this material looks highly similar to traditional natural rattan, making it a perfect alternative to its counterpart. As a modern, stylish material, synthetic wicker woven panels can be crafted in different patterns with various styles and colours.

Because of its natural beauty, versatility, durability and easy maintenance, this material is widely chosen by lots of project designers and architectural designs. No matter you are using it for your ceiling, wall coverings or facade constructions, plastic rattan woven panels can add a touch of elegance and sustainability to your spaces, which can easily turn any space into an aesthetic and relaxing paradise.

Product Specifications

When you come to select the suitable plastic rattan woven panel for your projects, it is essential for you to understand what product size you need. Before placing an order from LTR, you should measure the size of the target area that you are going to cover with the material. As a sophisticated plastic rattan supplier with years of experience in the industry, our rattan sheet materials can be produced by machines or by hand; and each production method features different characteristics and requirements.

- Machine Weaving: Normally, when you place an order, LTR will produce your artificial wicker panel by advanced weaving machines. That is because machine-weaving is the most cost-effective and efficient way for you, which can secure the product delivery time and help you start your projects as soon as possible.

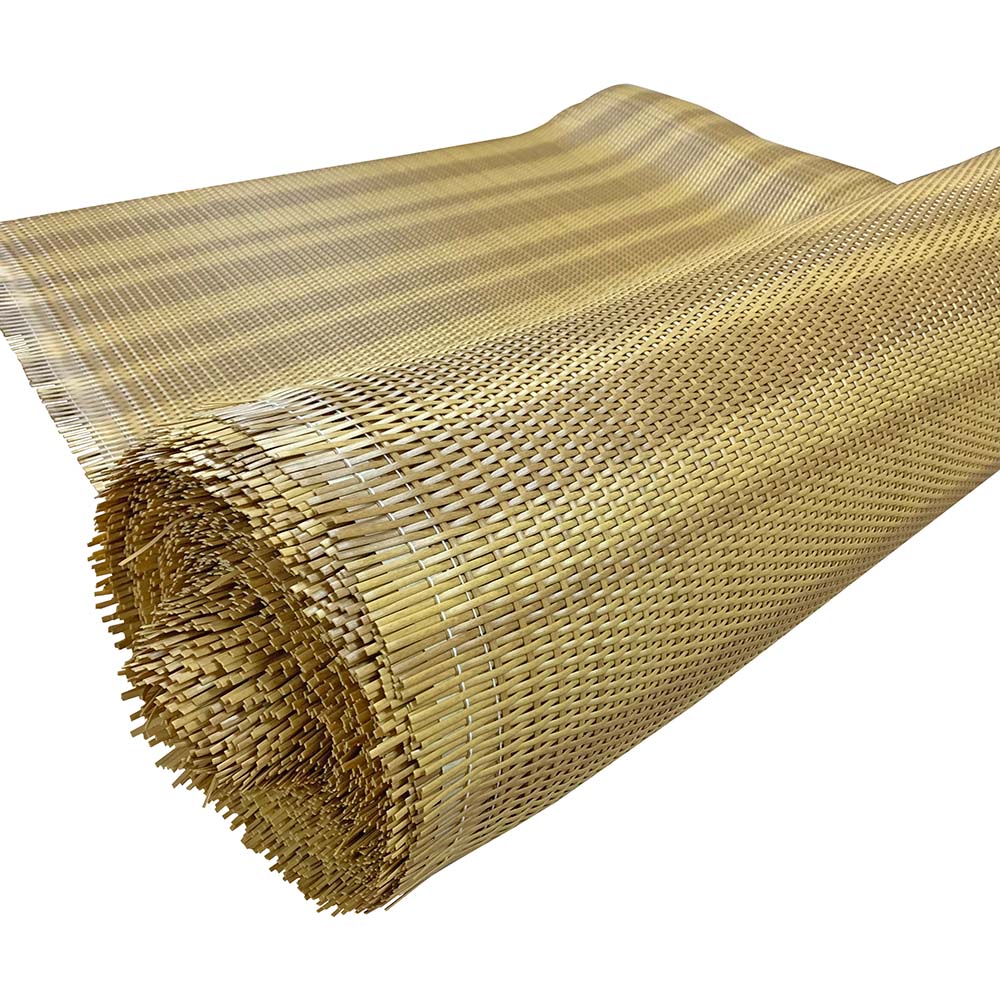

For machine-weaving rattan sheets, there are some restrictions that you should know about. First, LTR’s minimum order quantity is 300 square meters, and only flat plastic rattan and round rattan can be processed by machines. However, round rattan woven sheets are not that popular for people to choose from. The width of flat plastic rattan strips can only be between 7-9mm, with the thickness limitation of 1.2-1.5mm. Moreover, for machine weaving, the length of the whole synthetic wicker woven panel should not exceed 12-15 meters, and the width should not exceed 1.2 meters.

- Hand Weaving: Although machine-weaving is the prioritized choice for most customers, LTR’s hand-weaving rattan sheet is also popular to be selected since it can satisfy any special needs that machines cannot complete. For hand-weaving synthetic wicker woven panels, you can have more customised styles as craftsmen do not have so many restrictions like machine weaving. They can fulfil most of your project requirements with more sizes, patterns and rattan styles (flat rattan, round rattan, half-moon rattan, seagrass rattan, etc.) However, the only feedback on hand-weaving rattan sheets is that it is more expensive than machine weaving since it demands more time and efforts of labour.

If you are interested in more styles or sizes that I did not mention above, contact us now for your personal order!

Different Machine-weaving Patterns of Leisure Touch Rattan

At LTR, we are always dedicated to offering our valued customers with stunning, practical and durable plastic rattan sheets. No matter what styles your project need, Leisure Touch Rattan’s strong factory capacities and professional craftsmen can satisfy you! Here, I will explain 6 major patterns of LTR’s machine-weaving plastic rattan woven panels.

- Plain Wave

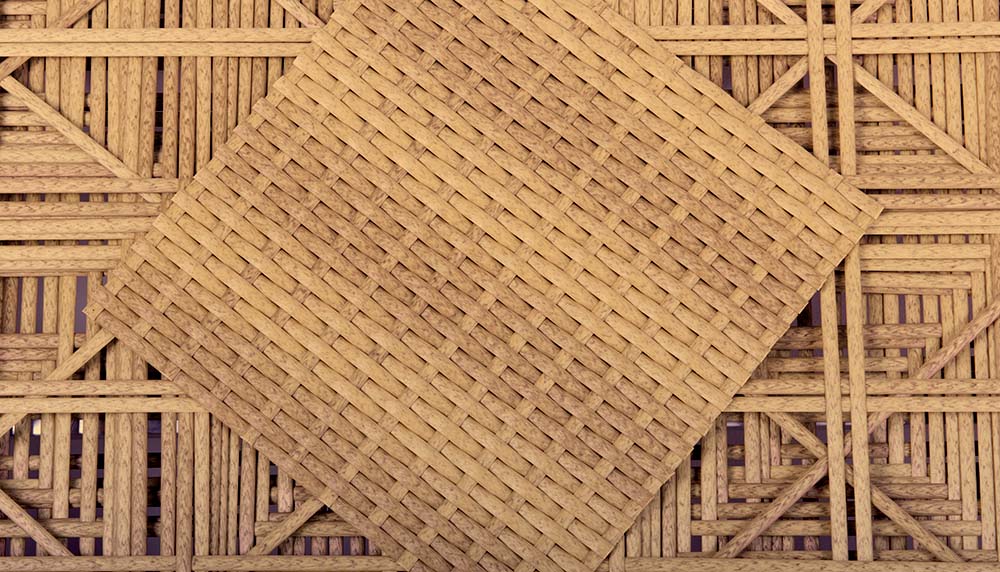

Among all the popular weaving patterns of LTR, plain wave is the most basic style that is widely chosen by designers and engineers. For this weaving pattern, plastic flat rattan strips are woven over and under in a simple, alternating pattern, creating a stunning visual effect of overlapping. With an uniform, grid-like structure, this style is simple, stylish and suitable for your wall, ceiling, roofing or furniture decorations.

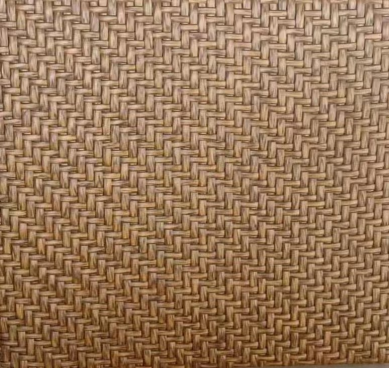

- Herringbone Weave- Single Colour

This pattern is also popular as its novel design can easily add charms to the surroundings. For this machine-weaving style, it features a “V” shaped pattern that resembles fish bones, forming a chevron-like design through alternating diagonal lines. The arrow-like pattern makes this type of plastic rattan sheet aesthetic and dynamic, best to be used for high-end construction projects.

- Herringbone Weave- Mixed Colours

Just like the single-colour herringbone pattern, this style also features a fish-bone appearance, but crafted with two different plastic rattan strips- either in different colours or styles. The striking “V” shaped pattern and mixed colours of this rattan sheet can easily add a dynamic and visually captivating element to both interior and exterior spaces, making it an excellent choice for those looking to make a lasting impression with their constructions.

- Wavy Weave

The wavy plastic rattan woven panel mimics the natural curves of waves, creating a fluid, undulating design that enhances your project aesthetics. In this style, the flat rattan strips are woven to form gentle, alternating curves, giving the material a soft, flowing texture. This pattern can easily add a sense of movement and rhythm to any surface, making it perfect for spaces where a dynamic or organic aesthetic is desired.

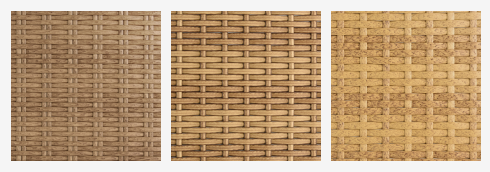

- Square Plain Weave

Similar to the plain weave pattern, the rattan strips of this style are also woven over and under to create an alternating pattern. However, the difference between this pattern and the classic plain weave pattern is that this style is woven by three strips together instead of one single strip. It is uniform, simple and stylish, suitable for your diverse construction and decoration purposes.

- Fancy Weave

Fancy weaving involves more complex or artistic designs to create unique patterns and textures. For example, this style is woven into exquisite square patterns with different colours, which adds a special decorative flair to your projects. It is normally used in high-end or custom projects to create a sophisticated and luxurious look.

In-stock Plastic Wicker Woven Mats

Once you have determined the type of wicker woven panel you need for your project, it is time to begin placing your bulk order. If your project is time-sensitive and requires fast delivery, you can take advantage of LTR’s existing inventory. With years of industry experience, LTR consistently maintains stock of three wicker woven panel options to fulfil your urgent orders and ensure quick delivery. If you are also looking for fast delivery for plastic rattan panel materials, here are three options that can meet your requirements.

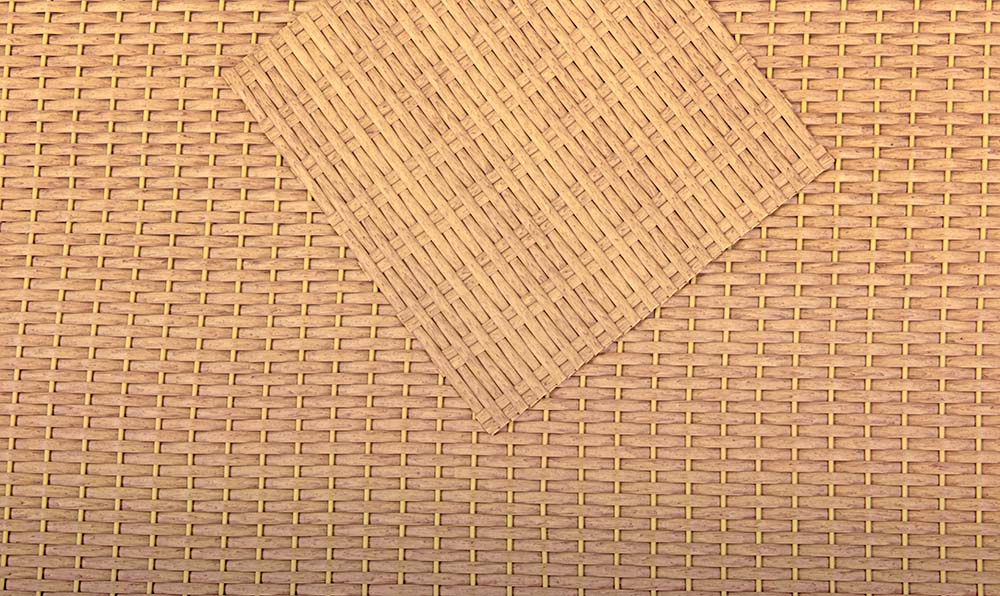

- Model 32449: For this style, light brown flat plastic rattan is woven over and under around the thin round reeds, which are placed vertically on the plastic rattan panel. It looks like the classic closely woven rattan panel but with a slight difference, making it suitable for diverse settings.

- Model 9490: This model is also available in stock to fulfil your urgent orders at LTR. If you prefer synthetic rattan panels that are natural and aesthetic, this model will be a good choice. It is woven overlapping with some hallow squares in between.

- Model 9810: This is a more exquisite style that requires more designs and details. It is woven by thin plastic rattan strips to create 3D patterns and textures, which is eye-catching and stylish. Your construction or decoration projects will be impressive with this model.

If you require more patterns for your synthetic wicker woven panels, you can contact us now to get your unique designs! All plastic rattan materials that are used to craft the above in-stock rattan panels are available to satisfy your needs!

How to Prevent Loosening of the Rattan Sheet Edges?

This is one of the most frequently concerned issues for most customers since it is possible for them to receive some loose products when they get the materials. However, at Leisure Touch Rattan, this kind of issue can be minimised or avoided as we are specialised in delivering high-quality plastic rattan rolls to our dear customers. Preventing loosening edges in woven materials can be achieved using various methods, depending on the different weaving processes.

For machine-weaving rattan panels: The plastic pre-woven wicker panels manufactured by this method will come with white ropes at all edges for reinforcing purposes, hence, the sheets will not easily lose during the shipping. If you would like to confirm further that the sheet edges will not lose, you can require additional tape for reinforcing purpose. LTR will not charge you for the additional tape reinforcement.

For hand-weaving materials: Different from the machine-weaving process, plastic rattan wicker panels of this weaving method do not have white ropes to prevent edges loosening. They need to be fixed using an electric soldering iron. After that, the rattan strips will be melted and stuck together for reinforcing purpose. You can easily see some holes on the surface. At this stage, some people often guess that a staple gun can be used to secure the edges. However, it is wrong. This tool is only used for rattan sheet installation, not edge reinforcement.

Hot pressing: This is a newer method of LTR to prevent loosening, which includes compacting the material into a single, non-unravelling piece. This is a super effective way as the whole material will be gone through a hot-pressing process and will not lose any more. However, this method is more expensive than traditional options.

Each solution ensures durability tailored to specific project needs, you can select the suitable edge-reinforcing methods based on your budgets and needs.

Material Selection for Your Synthetic Rattan Wicker Rolls

When selecting suitable rattan rolls for your projects, there are several factors to consider based on your different requirements:

- Fire-Retardant Options:

When people source pre-woven plastic wicker panels from us, they normally choose the standard materials that are not fire-retardant. However, if you request, LTR can fulfil your needs and produce plastic rattan rolls that can meet high-level building material standards and comply with fire-retardant regulations. However, it is important to note that adding fire retardants will impact the tensile strength of the material and reduce its toughness. For this reason, we recommend limiting flame-retardant rattan rolls to a maximum length of 5 meters. This ensures the material maintains both its beauty and practicality, avoiding issues such as breaking or loosening.

- Project Requirements and Lifespan:

Except the above factor, you can also choose materials based on your unique project needs and expected material lifespan. If your projects do not require high-level construction standards and expect to be replaced the materials after 2-3 years, you can opt for standard rattan rolls without the fire-retardant property. However, for long-term applications, such as durable building facades, we recommend building-grade plastic rattan rolls to you, which are designed to last up to 15 years.

Differences between Rattan and Rattan Wicker Panels:

Although some people have already understood what pre-woven wicker panels are, some people are still confused between this material and the classic rattan material. Here, I will briefly explain these two materials to you based on their unique characteristics and uses.

Rattan Material: In the furniture material industry, rattan material normally refers to rattan strips which are derived from the rattan palm plant. Rattan strips can be manufactured into diverse shapes and patterns such as flat, round, and half-moon rattan. For this material, it is primarily used to weave furniture and handicrafts, which require intricate handwork. Since these rattan items are often uniquely shaped, they cannot be woven by machines and rely on skilled artisans to weave custom designs and patterns.

Pre-woven Rattan Wicker Panel: On the other hand, this is a type of construction material primarily used as building decorations. It can be either machine-woven or hand-woven, depending on the desired style, pattern, and size. Machine weaving is suitable for standard flat or round rattan within specified size limits, while hand weaving offers greater flexibility for custom designs. In terms of its applications, it is widely used in ceilings, walls, roofs, and installations in commercial spaces like restaurants and resorts.

For more persosnalized options, please feel free to contact us for further details. LTR will help you create the most impressive construction decorations for your projects!

Manufacturing Process of LTR’s Synthetic Wick Woven Panels

Since plastic rattan sheets are woven into large panels by plastic rattan strips, their manufacturing processes are kind of similar. The panels also need to go through the first five production stages of plastic rattan to create high-quality materials. As a leading plastic rattan supplier in China, Leisure Touch Rattan’s strong factory capacities and strict quality inspection will ensure that all rattan strips and rattan panels are manufactured with the highest quality standards.

The first step of artificial pre-woven wicker panel is material preparation. During this step, only premier PE plastic material and other high-quality additives will be used by us. Then, the materials will go through an extrusion process by machine to form a desired shape. To create a unique pattern shape, moulding process will be done to achieve the required pattern and size.

After that, water cooling is needed to help solidify the plastic rattan into its final shape, which can effectively prevent deformities. Followed by the embossing process, automated machines are used in this step to produce different surface effects of plastic rattan, such as seagrass patterns and bamboo patterns. Now, the differences start here, from this step; plastic rattan strips are rolled into a Disc-shape and prepared for the machine weaving or hand-weaving process. After the synthetic plastic rattan strips are woven into large sheets, aesthetic, practical and durable materials are born for your projects.

Why Are Cane Webbing Rolls Softer Than Pre-woven Wicker Rattan Panels?

The difference lies in the unique properties of the materials used. Rattan cane webbing rolls are made from cane, which is derived from the outer layer of the rattan palm plant. This material is normally soft and elastic, making it a perfect material for decoration purposes instead of weaving furniture.

In contrast, the fibers used for synthetic wicker panels are different. They are the same rattan strips as those used in furniture weaving. These fibers are strong, sturdy, and stable, ensuring durability for structural applications; hence, rattan panels are widely used in construction projects. Because of their unique properties, cane webbing is inherently softer and more flexible, while rattan panels are designed for strength and resilience.

Another Elegant Alternative- Cane Webbing Rolls

If you are seeking materials for interior decoration—whether for walls, ceilings, or furniture accents—cane webbing rolls are an excellent option. They share a similar appearance to rattan panels since they both are derived from different parts of the same rattan palm plant and feature comparable weaving styles and patterns. However, cane webbing offers a softer aesthetic, making it an ideal choice for creating a warm and inviting interior.

Cane webbing is not only visually appealing but also easy to install and clean, providing a hassle-free decorative solution for your indoor design. Beyond our classic natural and artificial cane webbing, we now offer a new design that is made from premium plastic PE material. This durable version is designed for outdoor use, which can withstand different outdoor elements for several years.

If you are interested in purchasing these versatile and stylish materials to enhance your spaces, you can read this blog for more detailed information of cane webbing rolls.

Future Business Model for Artificial Wicker Panels

As an eco-friendly and durable construction material, plastic pre-woven wicker panels are widely chosen by most designers to create eye-catching roofing, ceilings, walls and facades. To satisfy our diverse customers’ needs, we currently offer custom plastic rattan rolls which allow for personalized patterns, sizes and colours. However, there is a drawback for this model, which demanding more time and effort for people to choose what they want.

Therefore, in the future, in order to help simplify your selection process, LTR’s R&D team is working on developing standard rattan roll options that have pre-designed patterns, colours and sizes. After these new products released, you can just choose between our wide product ranges or customize your unique materials! Please keep notice of our future launch of the standard rattan rolls, we will enhance both your indoor and outdoor spaces with our products’ exceptional natural beauty.

How to Select a Reliable Plastic Rattan Roll Supplier?

Choosing a trustworthy plastic rattan roll supplier is crucial, especially for projects requiring high-quality building materials. A poor choice will easily affect your project’s integrity and your company’s reputation.

When selecting a supplier, there lots of factors that you need to consider. For example, their industry experience, factory capabilities, case projects, problem-solving expertise, skilled workforce, and professional customer service. Additionally, it is also essential to check their material selection processes, quality inspection processes, product certifications, production efficiency, logistics, and after-sales support.

If you are looking for international manufacturer, please ensure the supplier can handle import/export and customs issues, as these will directly impact the smooth delivery of your bulk orders.

Leisure Touch Rattan, with decades of expertise, stands out in the industry. Their robust factory capacities, skilled personnel, strong problem-solving abilities, and superior product quality guarantee efficient production and delivery of high-grade materials, which can easily enhance your project’s aesthetic and durability.

Frequently Asked Questions of Synthetic Wicker Woven Panels

- What are some advantages of an artificial wicker woven panel?

This material offers numerous advantages, making it an excellent choice for various applications. Because of its high-quality PE plastic material, it is eco-friendly, UV-resistant, and anti-fading, ensuring long-lasting beauty even under harsh sunlight.

Unlike natural materials which are sensitive to pests and rot, this synthetic option provides peace of mind and effectively reduces maintenance concerns. With its robust property, this material is highly durable and well-suited for facades and other demanding environments. They bring a natural and aesthetic appeal to any space while being easy to install and virtually maintenance-free. For a combination of sustainability, functionality, and style, synthetic wicker panels are an exceptional option for lots of outdoor constructions.

- Can synthetic wicker woven panels be used outdoors?

Sure, they can! Just like what I mentioned above, artificial rattan panels are primarily made of high-quality PE plastic material, which has lots of benefits to make it survive in harsh outdoor settings. Unlike natural rattan panels, the synthetic options will not suffer from changing weather conditions. If you are looking for natural and aesthetic construction material, it will be a good choice!

- What are the common applications of this material?

Unlike cane webbing roll materials, artificial wicker rattan panels belong to construction material, which are normally used in different construction applications such as ceilings (click to see our real case examples), roofs, walls or artistic facades. It is common to find this material in scenarios where tropical sense or relaxing ambience is needed such as restaurants, resorts, coffee shops, shopping centers, real estate, hotels, apartments, yoga centers and exhibition halls.

Furthermore, it is sometimes can be used in furniture making such as room dividers, fence, cabinet decorations and so on. By utilizing this simple, practical and stylish material, your projects will leave a great impression to your clients!

- How long is the product warranty for pre-woven plastic wicker panels?

Actually, LTR’s product warranty for different products might differ, depending on their materials used and additive added. For general plastic wicker sheets, the product warranty is around 2 years. Meanwhile, for the construction level rattan sheet which demands higher quality, fire-retardant property and safety standard, can normally last for 15 years as they need to be stronger to survive.

- How to install artificial wicker woven panels?

Many people might worry about the installation process of this material when they purchase it. It is one of the most concerned questions that people often ask. Actually, installing plastic rattan woven panels is not difficult. As a sophisticated rattan sheet supplier, Leisure Touch Rattan will offer you comprehensive help about how to attach this material to your building. If you would like a detailed explanation, here is an ultimate guide for you! (Click to see)

Simply speaking, the first step you need to do is to prepare all tools you need such as ruler, knife, marker, power tools, glue, nails or staples. Then, you should make sure the installation area and plastic rattan panels are dry, flat and smooth. Next, you will need to measure and cut the rattan panels based on the sizes you need. After placing it to the surface, glue can be used to fix the materials. If you would like to enhance its stability, staple guns or nails can be used to reinforce the materials.

Is it easy? If you have any further issues about the installation, no worry! LTR is here to help!